Delta 15 Amp 13 in Portable Thickness Planer Review

Best Benchtop Thickness Planer

Benchtop thickness planers are an essential piece of equipment for whatsoever woodshop. These planers are an fantabulous option for pocket-sized abode woodshops and contractors that need a portable option. While non big and powerful as full size store thickness planers, benchtop thickness planers are notwithstanding very capable of effectively planing a wide range of wood products. Thickness planers allow users to buy a wider range of raw woods materials (often at cheaper prices) and factory the wood to the exact dimensions needed for a project.

Thickness planers perform 3 important tasks for woodworking and carpentry:

- Smoothing rough stock

- Making the faces of a board parallel

- Bringing stock to a consistent and specific thickness

Thickness planers are primarily a woodworker's tool, however they are also often used by finish and trim carpenters in the store and occasionally in the field. With sharp knives the surface of a planed lath is often smooth plenty for pigment or even clear finishes. For our testing nosotros chose the following planers (follow links for manufacturers page on each planer):

- Delta 22-555

- Delta 22-590

- DEWALT 734

- DEWALT 735X

- Makita 2012NB

- Porter Cable PC-305TP

- Ridgid R4331

- Triton TPT 125

For this caput-to-caput exam we focused on planing several different wood species, the surface finish, the power, and pricing. Below is a detailed discussion of our testing and evaluation.

Purchase Now

Features and Specifications

Portable thickness planers have to squeeze a lot of power into a small footprint that can exist reasonably moved around a shop or to a job site. But even within this limitation there are some substantial differences in size and weight of the machines we've tested. But every automobile is capable of planing boards 12 to xiii inches wide and six inches tall. The specifics and the differences are bear witness in the lists below.

Thickness Planer Testing Procedures and Evaluations

For this evaluation nosotros used several types of forest in society to get a skillful perspective on performance. Nosotros used the post-obit boards in our testing:

- 1×4 Mahogany decking

- 1×6 White Oak

- 1×vi Hard Maple

- one x 8 Poplar

For this bench-top thickness planer caput-to-caput nosotros evaluated several categories including:

- Pre-Test Inspection and Adjustment – We looked at how level the infeed and outfeed tables were, we adjusted them, and noted how easy or difficult the procedure was.

- Feed Rate (Speed) – We measured the no-load feed rate of each planer and compared that to the feed rates under load for different material types. In our opinion this provides a sense of how powerful the motors are.

- Maximum Depth of Cut Operation – For this evaluation nosotros measured the amp draw for each thickness planer under load planing several unlike types of wood. Once more in our opinion this helps compare the strength of the motors during the planing procedure.

- Depth of Cut Accuracy – For this evaluation we wanted to look at how accurately the planers remove a specified depth. Each planer has a punch that when turned a specified corporeality will theoretically remove a given depth in a single pass. Nosotros compared how accurately each planer was able to remove a stock-still depth based on the dial.

- Snipe Evaluation – Snipe is fairly mutual with thickness planers, especially benchtop models like the ones in this evaluation. We compared the length of snipe for each planer and material type.

- Surface Finish Evaluation – Ultimately the surface finish is actually important, especially if the finish reduces the fourth dimension to prepare the piece of work slice of pigment, stain and or clear finishes. We applied blue chalk to the surface of the boards in social club to ameliorate our visual inspection combined with a physical inspection (feeling the surface) to rank the surface terminate for each planer.

- Bract Change Evaluation – Lastly we measured the time to do a blade change on these planers. Irresolute blades is a necessary task for whatsoever thickness planer and then nosotros wanted to see how they compared.

- Warranty Coverage – We summarized all the warranties.

- Pricing – We list the current pricing at the fourth dimension of publication.

Pre-Exam Inspection and Adjustment

Prior to testing twenty-four hour period, we unboxed the bench-top thickness planers and set up the equipment with grit collection manifolds (if so supplied) and put on accessories. In particular, we adjusted the in-feed and out-feed tables to ensure each were level with the planer bed.

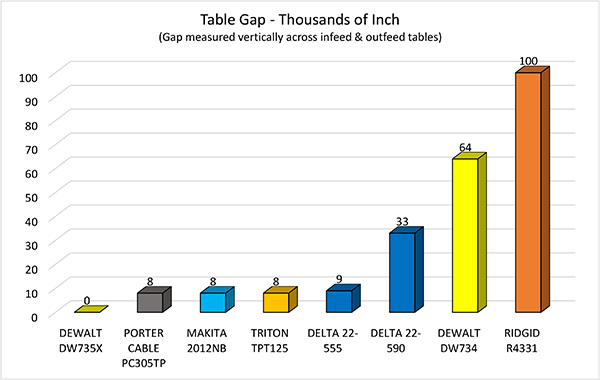

It's extremely important that the in-feed and out-feed tables are level in order to have consistent and representative tests. The as-shipped accuracy of the tables varied betwixt the different models.We adapted the in-feed and out-feed tables separately and then checked for level across the entire automobile. The worst measured vertical divergence from flat at the edge of the outfeed tabular array nearly 1/8" in a higher place the surface of the planer. All of the machines except the DEWALT DW735X needed small-scale adjustments to reach a level surface.

Most of the planers use a bolt to adapt the table vertically with a captured nut to hold the adjustment bolt in place. All of the units had a similar table adjustment but one. We were very impressed with the Makita planer and its setscrew adjustment. The Makita machine had, by far, the easiest adjustment method of all of the planers. The four setscrews were easy to reach and we plant information technology like shooting fish in a barrel to dial in the proper adjustments.

We're not going to rank this category equally nosotros feel a bench-height shop tool similar this will always require some setup and fine tuning. Of the 8 planers Makita definitely has the best system for making those adjustments.

Dust Drove

While we didn't rank dust collection it's worth discussing briefly. Thickness planers produce high volumes of wood chips and grit, probably more so than most whatsoever other tool in the woodshop. All of the planers (with the exception of ane) comes with a dust shroud and so the planers tin be attached to a grit collector. The Porter-Cable does not come with a shroud (a subscriber on our YouTube channel says one is bachelor for the PC from Delta, Delta role number 50-359 , so maybe you can find one). So anyone that is interested in this model should plan on lots of clean upwardly after planing. All of the other planers tested worked well when fastened to the shop grit collection with little variation in performance amongst the dissimilar models.

Feed Rate (Speed) – Winner DEWALT DW735X

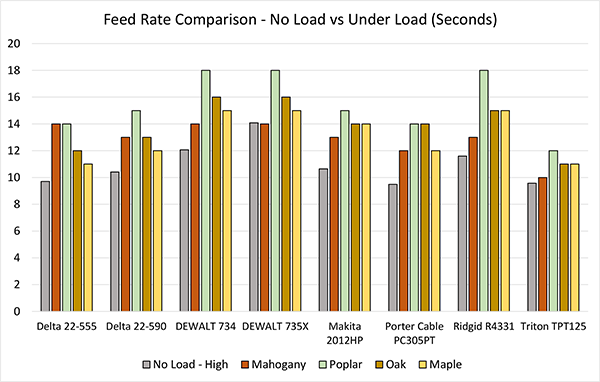

We recorded the no-load feed rates for each planer. To do this, we adjusted each planers depth until it contacted the wood only had non reached the depth where the cutter blades striking the woods. In lodge to tape the no-load feed rate for a section of wood 45″ long (same length of the samples we'd exist running through the planer), we used a longer board (60″) with two marks nearly each finish that were 45″ apart. This allowed us to visually time the 45″ section as it passed by a reference point on the planer. For each planer, we ran this test 3 times and used the boilerplate of these times for a comparison between the no-load and fully loaded feed rates of each automobile.

The graphic above shows the no-load feed rate for each automobile along with the feed rates of each auto for each sample of wood. Nosotros were looking to see which planers had plenty power to sustain the no-load feed rates throughout the different boards that were planed.

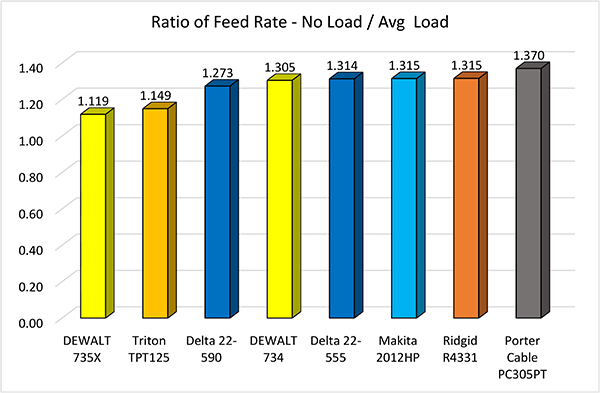

Above you tin see a graphic showing the ratio of the no-load feed charge per unit compared to the boilerplate loaded feed rate (average feed rate for the materials we planed). This only gives a skillful relative comparing of how the motors performed nether load. The DEWALT 735X and the Triton TPT125 were able to keep the feed rate much closer to the no-load rate compared to the residue of the field.

Nosotros did rank this category as it's a keen way to evaluate the power of the planers. The top three included the DEWALT 735X, Triton TPT125 and the Delta 22-590.

Maximum Depth of Cut Performance

We wanted to know how each machine performed at maximum loads (which results from cutting at the maximum depth in a single pass that the manufacturer recommends). More specifically, we wanted to know which planer pulled more power (maximum amp depict) and which one had the all-time feed performance relative to its no-load status.

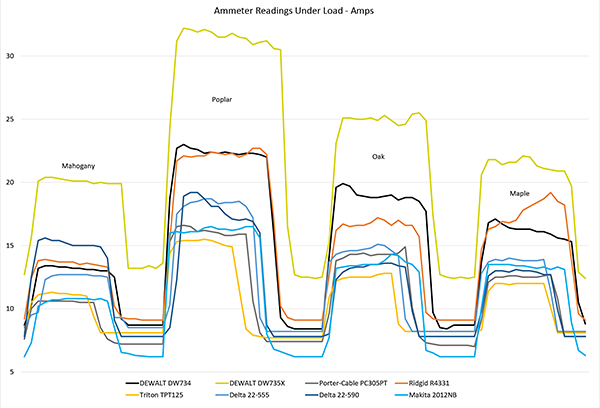

During this test, nosotros set each planer to its maximum depth of cut (every bit recommended by the manufacturer) – usually 3/32 inch. We ran four species of forest through the planers and recorded the time for the cut and the amperage profile for each cutting. Each wood sample for each machine was 45" in length. This was the same length of the no-load speed test. Our team set upwards a FLUKE 3001 FC recording ammeter that measured values on a one 2nd interval and sent the data via wireless link to our computer for later analysis.

The wood samples nosotros used in this exam were 1×four Mahogany decking, one x 8 Poplar, 1×6 Oak and 1×vi Maple. We knew that the 1×8 Poplar at a maximum cut depth would revenue enhancement the power of these planers. We as well wanted to encounter how the different hardwoods would exercise the planer capacity.

While we're not ranking this category nosotros do experience the information is interesting and informative. As you can see above the DEWALT DW735X pulls some serious amps under load. It points to the much more than powerful motor in that unit of measurement. The power divergence was clear during the planing operations as information technology didn't seem to care what we ran through it. But it'south important to note if y'all're going to buy the DEWALT DW735X you MUST take a dedicated 20A excursion as it's non going to run well on a 15A circuit.

Depth of Cut Accuracy – Winner DEWALT DW734

Demote-top thickness planers take a punch used to move the cutting heads up and down to gear up the depth of cutting. On each model the dial indicates how far the heads motility upwardly and down per revolution of the dial. We used calipers to measure the average thickness of each woods sample before and afterwards a pass to remove 3/32″. We then compared how accurately each planer was able to practise that and listed the average deviation from the 3/32″.

As you can meet above, the DEWALT DW734 performed the best with an average deviation from 3/32″ of just under 2 i-thousandths of an inch. The DEWALT DW735X came in 2d with just over 4 1-thousandths of an inch followed by Ridgid R4331 at just over 5 i-thousandths of an inch. Last identify was the Triton that averaged just over 3 hundredths of an inch deviation.

Snipe Evaluation

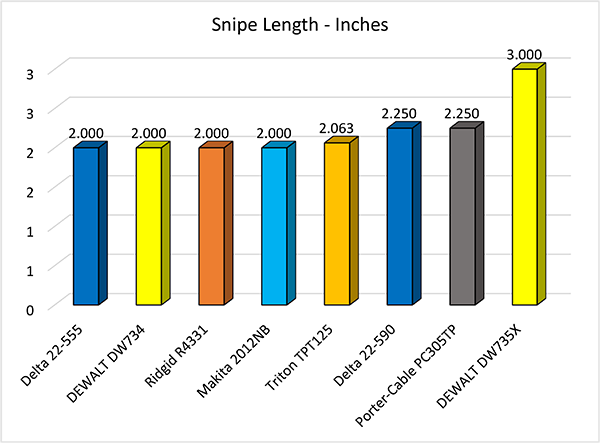

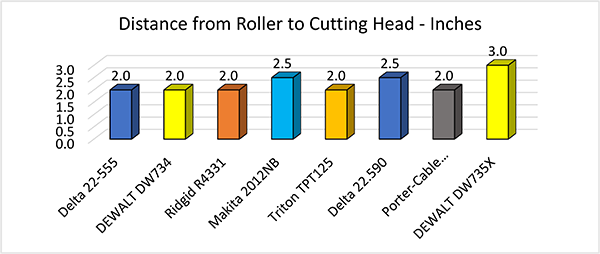

We tested how much material would be 'lost' to snipe. We had already adjusted each planer'southward tables to exist apartment, and level to the planer bed, prior to the snipe exam.

The TBB Crew selected the maple forest for the snipe examination. Nosotros thought the lighter color and tight grain structure of maple might testify the location and the depth of any snipes meliorate than the other woods. For this test, we fix all of the planers to a uniform depth of 3/32". Each piece of wood was started at the starting time roller of the planer and nosotros left our hands off the sample until it stopped past the outfeed roller. Side by side blue chalk powder was rubbed onto the final 6" of the lath in lodge to make the snipe condition stand up out visually. Finally nosotros marked the 'ridge' of each snipe cutting so that nosotros could measure the amount of textile that each planer produced for waste if the snipes were cut off to apply the uniform thickness textile.

What's interesting nigh this data is how well the snipe length correlates to the distance of the rollers inside the planers from the cutting heads. The length of snipe on all the models we tested near mimic this altitude. The nice thing here is the snipe should be anticipated for each model and let users to plan accordingly. Users of the DEWALT DW735X will ultimately "waste material" more material over the life of the planer. However, with all the planers having relatively the aforementioned amount of snipe we're not ranking this category either but rather letting yous see how they all compared.

Surface Cease Evaluation – Winner DEWALT DW735X

Another consideration when evaluating bench-superlative thickness planer performance is the surface cease. Demote-tiptop thickness planers use a ready of rotating blades to "shave" off the surface of the lath being planed. As a result of the rotational bract motility, "small bite size" chunks are removed equally each blade contacts the surface, resulting in very slight ridges that can be left on the surface of the planed board (often referred to as milling marks).

Planers can also tear out minor chunks (scallops) from the surface. Between the milling marks and scallops the board could require more or less sanding to create a finished surface that will take pigment, stain or clear finish well.

We applied blue chalk to the surface to highlight the milling marks, and scallops, for a visual inspection. We also evaluated the smoothness by simply feeling the surfaces. While very subjective, we ranked the planers based on the samples of Maple shown below.

While all the planers produced a "smooth" finish to the touch, there was quite a variation of smoothness resulting from the milling marks and scallops. The DEWALT DW735X was by far the all-time end of all the samples we planed. The amplitude of the milling marks was consistently smaller and at that place was very trivial "scalloping" of the surface compared to all the other planers. This is likely attributed to the powerful motor and excellent blades. In improver, the 735 has three blades in the cutter head. Coming in 2d place was the Triton TPT125 followed by the Ridgid R4331 in tertiary place. Both the Triton and Ridgid had similar results. Coming in 4th was the Delta 22-590 with minimal milling marks just noticeably more scalloping.

Blade Alter Evaluation

Is it easy or difficult to alter out the blades on whatsoever given machine? Our crew took each automobile and armed with the instructions and the tools in our workshop changed out each bract on each car. Evidently, the planers with three blades would take more time than the machines with two blades. But is this procedure easier on some machines that others?

As y'all tin run across higher up the times required to change the blades on the planers varied from just over xi minutes to simply over 25 minutes. The reality is a user might change blades once or twice a twelvemonth (twice would be heavy employ) so the divergence from 11 to 25 doesn't seem enough to warrant why you might buy one over another model. Therefore we're non going to rank this category, simply share the information and so you can see that bract changes are not overly complicated.

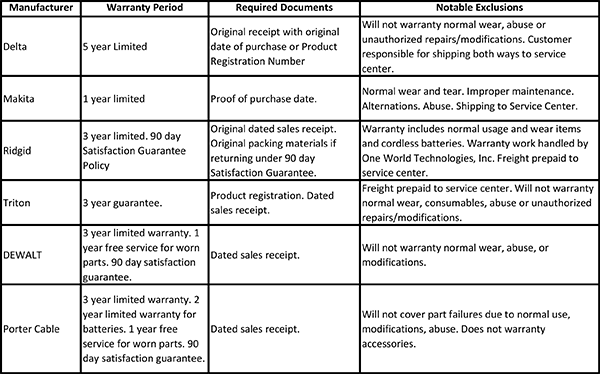

Warranty

Warranties are actually important to some users, and many of yous have asked us to include them in our reviews. Below is a list of the warranties applicable to the planers nosotros tested. While ranking the warranties might seem simple, nosotros've decided to only list them rather than rank them. Ultimately, warranties tin be a tough issue, and how hands you can get warranty service is probable to be as of import as how many years the coverage is. Nosotros'll permit you make your own determination on which warranty appeals to you.

Price Evaluation – Winner Porter-Cable PC305PT

Price is oft a huge function of the equation when determining what tool is all-time for y'all. There'south a huge difference in pricing in this test from the low $300 range up over $600. We are ranking these straight on the lowest to highest with prices available at the time of publication. Nosotros realize there is a "value" proposition that many will look at, but that volition factor into our overall ranking when price and the other categories are combined. Finishing with the best price is the Porter-Cable PC305PT at $320 and rounding up the well-nigh expensive is the Makita 2012NB at $650.

Overall Winner, Best Benchtop Thickness Planer – DEWALT DW735X

Hither we are again trying to rank the tools in our Head-to-Head and give you a winner. The more of these we exercise, the more we learn, and in this evaluation nosotros've taken a slightly unlike arroyo. Some of the categories that we set out to evaluate we decided not to include in the concluding ranking. However, we did provide information from that category as we feel information technology'southward valuable to some readers.

Besides, the more nosotros practice these the more some folks comment almost how they would weigh unlike categories differently. That'due south all peachy feedback, ultimately we need to come up upwardly with a winner (our winner) just each of yous tin can take the data we've presented and weigh the results differently to best match your needs and come up upward with your ain winner.

Beneath is a table showing how each of the 8 planers stacked up in the 4 categories that we counted in our concluding evaluation. Finishing in first place by a large margin was the DEWALT DW735X. This wasn't a surprise to us as several of us accept used this planer for quite some time and it's really the all-time benchtop thickness planer on the market without a dubiousness. What did surprise the states was the 2nd and third place finishes of the Triton TPT125 and the Ridgid R4331. If you're looking for a good performing affordable planer the Triton is certainly worth noting. Ridgid has a nice line of woodshop tools that get unnoticed often and information technology was nice to see them perform so well in this category.

While the Delta 22-590 finished near the finish in this evaluation, the team felt it was also a squeamish planer to consider. The Makita is a very well-built planer with some nice features but the toll wasn't as competitive and the surface finish, at least on the materials nosotros tested, wasn't nearly equally good as some of the other models.

Purchase Now

All-time Benchtop Thickness Planers – Head-to-Caput Video Review

stephensonthation.blogspot.com

Source: https://www.toolboxbuzz.com/head-to-head/best-benchtop-thickness-planers-head-to-head/

0 Response to "Delta 15 Amp 13 in Portable Thickness Planer Review"

Post a Comment